B.RCLab disposes two thermal vacuum (TVAC) units: a large one, and a small one. Both are used to regulate in temperature an instrument under test for temperature dependent quantities such as wavelength calibration.

B.RCLab disposes two thermal vacuum (TVAC) units: a large one, and a small one. Both are used to regulate in temperature an instrument under test for temperature dependent quantities such as wavelength calibration.

1. Equipment

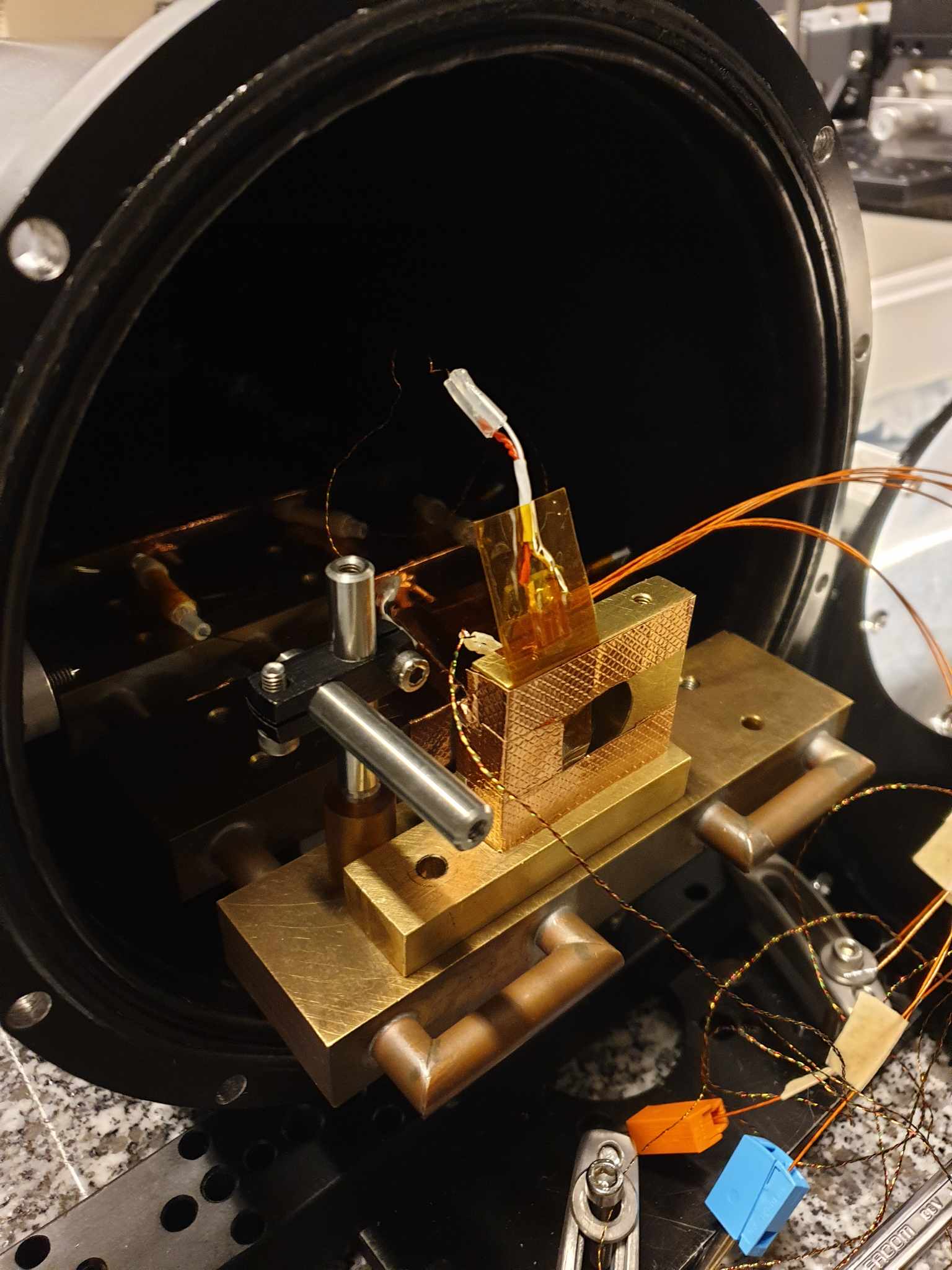

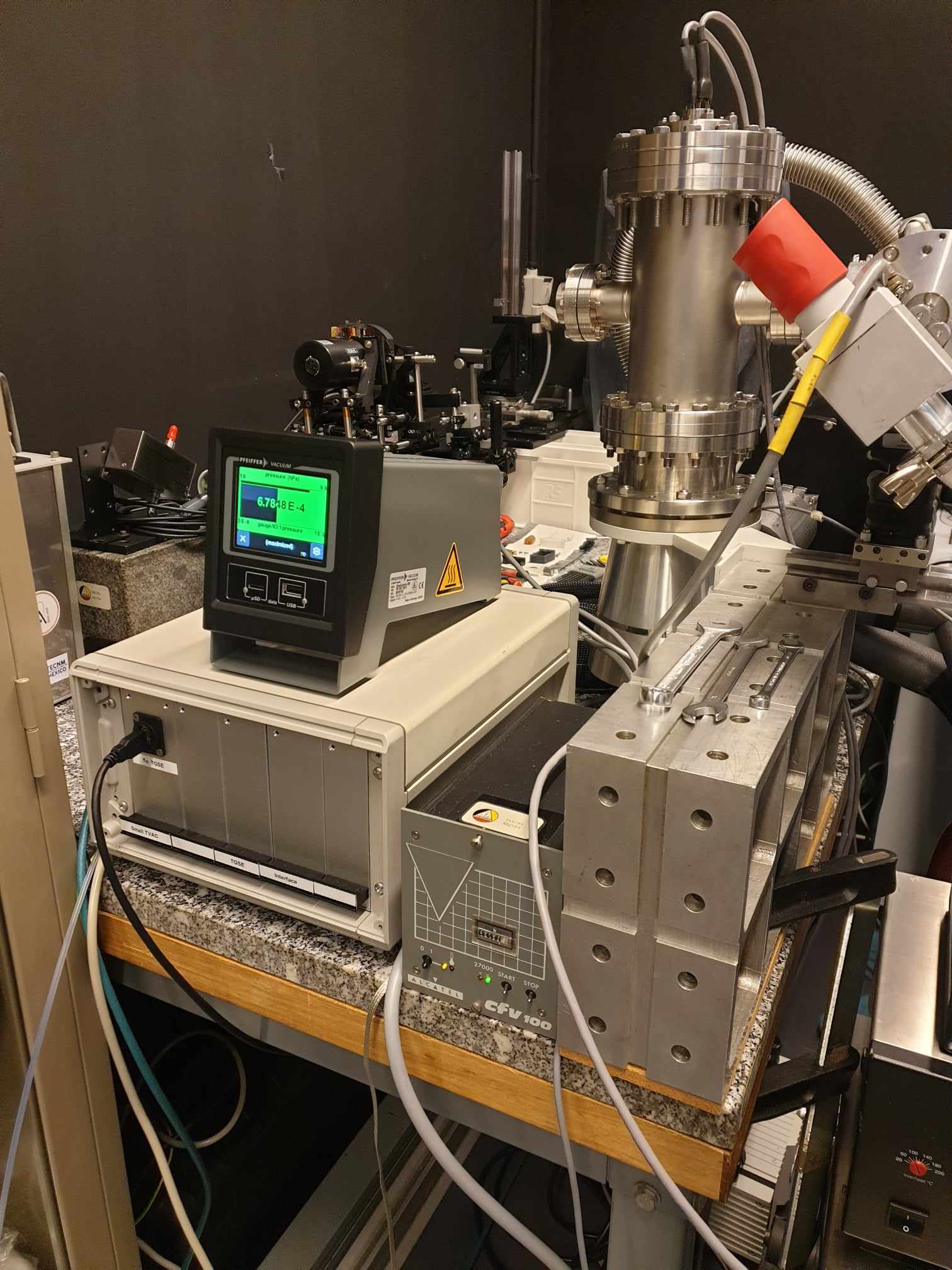

The small TVAC unit consists of a cylinder with a volume of about 20 dm³. It is equipped with a cold plate and a window.

The cold plate is made of a 2 cm thick copper plate through which a fluid can circulate freely in a closed circuit. This circuit is connected to an external cryostat (Huber CC240), which is also used to regulate the fluid temperature. The heat transfer fluid used is a mixture of MonoEthylene Glycol (MEG) and water. Temperatures ranging from -40°C to +90°C can be achieved depending on the mixing ratio.

Additionally, six 3-wire and one 4-wire calibrated PT-100 sensors are provided for telemetry and monitoring. These sensors are flexible and can be placed anywhere on the device under test. As for the vacuum unit, it consists of a primary pump and a turbopump, allowing for achieving a vacuum in the range of 10-4 mbar. Finally, a pressure gauge is used to monitor the pressure inside the cylinder in real time. Figure 1 illustrates the small TVAC unit.

2. Electronics

An Arduino Uno is connected to six MAX31865 Resistance to Digital (RTD) Converter modules to convert the resistance value of the PT-100 into calibrated and meaningful temperature values using the Callendar-Van Dusen equation. This equation describes the relationship between the resistance and temperature of platinum resistance thermometers.

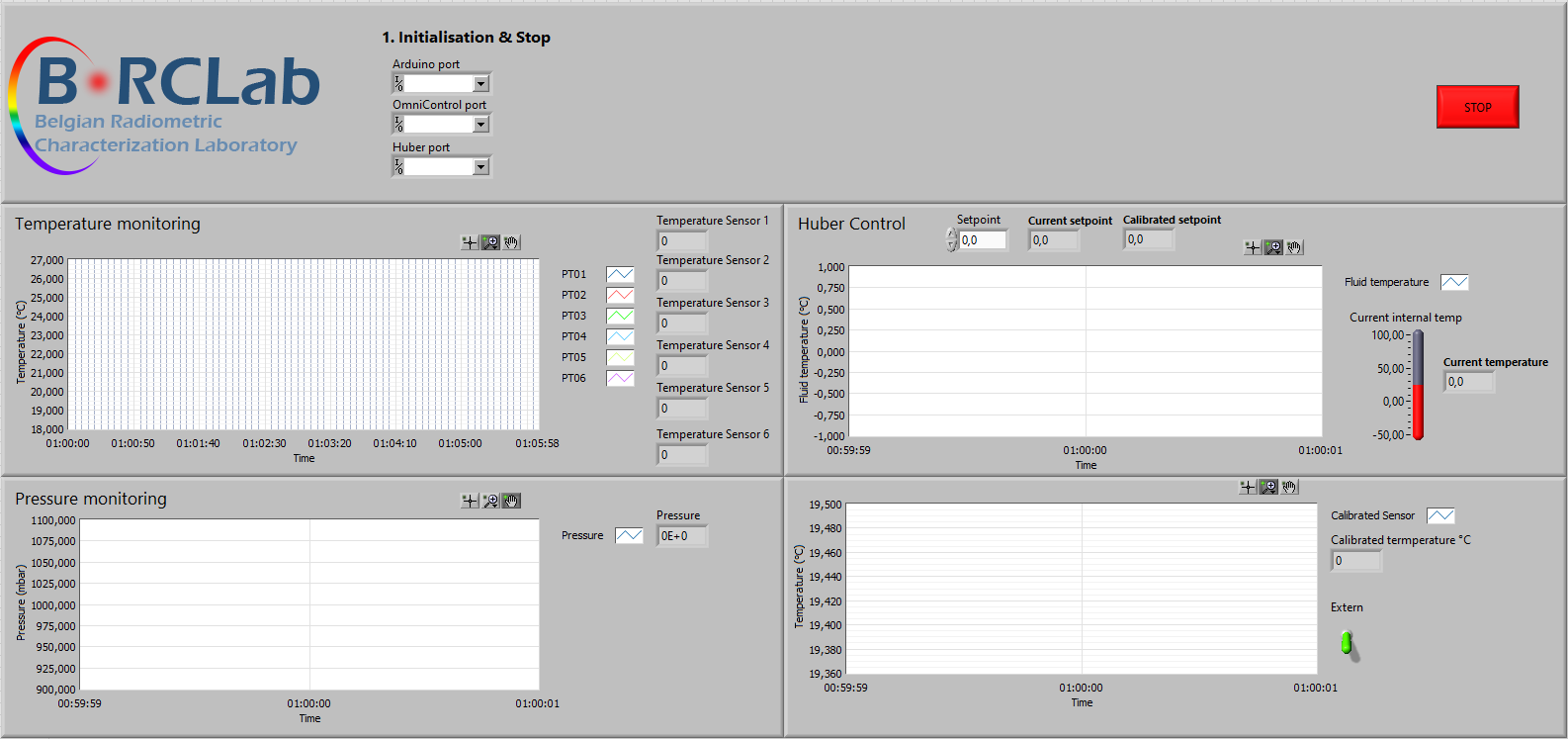

To remotely control and monitor the fluid temperature, as well as monitor the temperature of the seven PT-100 sensors and the pressure inside the TVAC, a dedicated LabVIEW software is used. Figure 2 illustrates the graphical user interface (GUI) developed for this application.

The temperature of the calibrated sensor is read using an NI DAQ device.

3. Applications

The small TVAC unit is used for conducting thermal tests on small equipment, including AOTF, optical subsystems, and small spectrometers. Various parameters such as Dark Current (DC), linearity, Read-Out Noise (RON), defective pixels, etc., are temperature-dependent. Consequently, this system has been designed to accurately determine the variation of these parameters with respect to temperature.

| Temperature range | From -25 to + 50°C |

| Light source | Laser-Driven Light Source (LDLS) using a focused laser beam to generate and maintain plasma between electrodes |

| Illumination |

Polychromatic in UV-VIS-NIR |

| Vacuum level | Room pressure down to 10-4 mbar |