B.RCLab disposes of two thermal vacuum chambers (TVAC): a large and a small one. Both are used to regulate in temperature an instrument under test for temperature dependent quantities such as wavelength calibration.

B.RCLab disposes of two thermal vacuum chambers (TVAC): a large and a small one. Both are used to regulate in temperature an instrument under test for temperature dependent quantities such as wavelength calibration.

1. Equipment

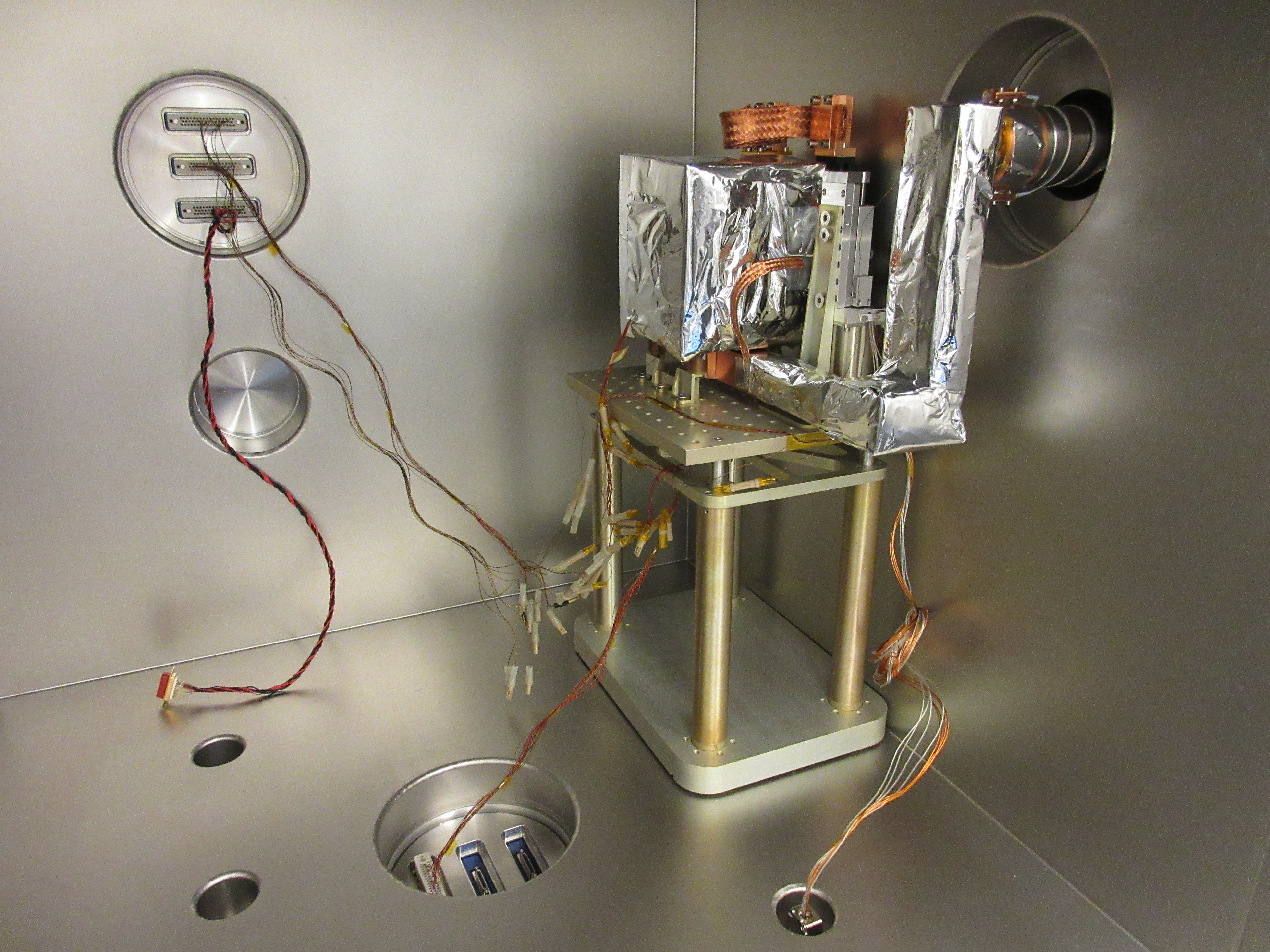

The large TVAC unit consists of a cubic chamber with a volume of 420L (75 cm per side). It is equipped with a cryocooler, and a CaF2 viewport (interchangable by a ZnSe viewport if required).

The cryocooler in use corresponds to the model CS104FT from ARS (Advanced Research Systems) and provides a cooling power of 60 W at 77 K. The cold head of the cryocooler, inside the vacuum chamber, is thermally connected to a cold plate where the sample/device can be installed. It is made of oxygen free high-conductivity (OFHC) copper and contains two temperature sensors and two heaters to perform thermal control (the cold head of the cryocooler has an additional thermal control loop).

As currently implemented in the facility, the setup can thermalize devices between 50 and 382 K with a precission of 7 mK. The maximum cooling rate of the cryocooler in its current configuration is about 1 K/min.

The vacuum chamber is designed to operate with the pumping system continously active, even during measurements. Despite the vibrations that might be induced by the cryocooler and the pumping system itself, the mount where the cold plate is installed is able to encounter any vibration. The pumping equipment allows keeping a pressure level below 10−6 mbar.

Figure 1. Upper view of the frontal door of the large TVAC (left). Current internal view of the large TVAC, including the mount for the thermalization of the sample (right).

2. Electronics

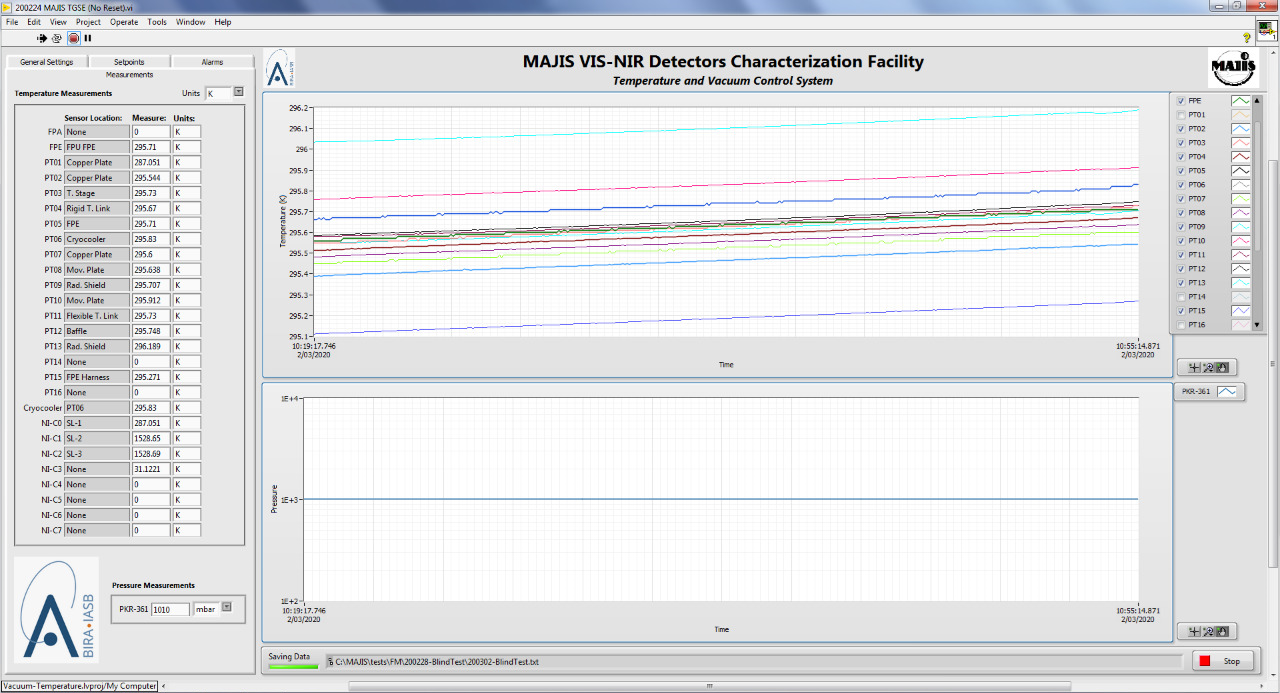

A LabVIEW interface is used to monitor up to 24 temperature sensors in real-time besides the pressure conditions inside the vacuum chamber. We count with one LakeShore 336 and two LakeShore 335 devices that allow us the use of up to six PID temperature control loops, and the possibility of configuring alarms for the protection of sensitive devices. If required, a thermal security system can be activated to protect the sample from undercooling and/or overheating thanks to the configuration of these alarms. The LabVIEW interface is remotely accessible from outside the cleanroom where the large TVAC is installed.

As part of the safety measures of the system, a robust security rack was developed to protect the vacuum chamber from overpressure and/or vacuum losses due to leaks and pumping failures. The pressure gauge used for the monitoring of the chamber has 30% of accuracy between 10−9 and 103 mbar, and a redundant gauge is also available if needed.

Figure 2. LabVIEW user interface of the large TVAC. The data acquired during measurements is continuously backed up in the servers of BIRA-IASB.

Figure 3. Control panel of the security rack. Some functionalities are accesible from the LabVIEW user interface of the large TVAC.

3. Applications

The large TVAC has been extensively used during the characterization of the MAJIS/JUICE detectors (in combination with the VIS-NIR radiometric facility), and more recently, it has been used for the thermal tests of the GRASS project.

In a near future, the possibility of performing radiative cooling inside the large TVAC will be implemented. In this configuration, the radiation from the room temperature walls of the vacuum chamber will be blocked by inner cold walls in contact with the cold head of the cryocooler.

| Nominal vacuum level |

< 10-6 mbar |

| Temperature range | 50 K to 382 K (-223 °C to +109 °C) in a single cycle |

| Thermal stability |

PID control loops with 7 mK precission |

| Working environment | ISO-5 (Class 100) cleanroom |

|

Viewports |

CaF2 (0.2 µm - 7.0 µm) ZnSe (2 µm - 14 µm) |

| Device/Sample safety |

Temperature and pressure monitoring in real time |

| Sample safety |

Room pressure down to 10-4 mbar |